Lifting the lid on manufacturing’s digital future

10 January 2020

What happens when you put manufacturers, tech specialists and futurists in one room? Manufacturing Lead Anne Campion shares what we learnt from a fascinating event on the digital economy and emerging technologies, from the Internet of Things to augmented reality and back again.

The future of manufacturing in the UK is an exciting prospect. Advanced digital technologies from internet-enabled sensors to virtual reality headsets are reshaping the sector as we know it, and thanks to initiatives such as Made Smarter, small manufacturers can join the revolution.

Nevertheless, technology should never be adopted for technology’s sake – businesses need to plan ahead and understand how different solutions can be harnessed effectively. To that end, we teamed up with our sister Green Technologies and Services team in November to bring together a roomful of manufacturers, tech specialists and futurists to lift the lid on the emerging digital landscape. Kindly hosted by Squire Patton Boggs in Manchester, the event was a glimpse into the future and an opportunity for some local businesses to show how digitalisation is working for them.

Digital futures

We were excited to welcome Mike Ryan, Manchester-based futurist and co-founder of ethical AI agency Morse, as our first speaker. He opened the discussion by introducing four possible digital futures that lay ahead of us. One; a future of relentless innovation where start-ups are king and long-lasting companies become a thing of the past. Two; a future where societies and governments take stronger control over technology and limit its applications. Three; a future where corporates dominate, with ownership of technology consolidated into fewer and fewer conglomerates. And four; a future where rising social responsibility shifts technology use towards social and environmental goals. The optimum scenario, Mike argued, is one that takes in the best parts of two and four – using technology in a way which puts humans and the environment first.

Automation

One local SME trying to put this into practice is Rochdale-based manufacturer Crystal Doors. After being inspired by a visit to Siemens’ high-tech factory in Congleton several years ago, Managing Director Richard Hagan has embarked on a relentless journey to embed Industry 4.0 technology into his business and has tied it to ambitious environmental goals.

Crystal Door’s biggest investment to date is a self-learning dust extractor system which autonomously monitors 24 machines, ensuring smart energy consumption and maximum environmental performance. The system can predict maintenance needs and is even able to identify which machine is making the most money for the company.

“Industry 4.0 is a journey everyone needs to go on”, Richard told the room. “I have not got a smart factory yet. I started four years ago and I’m still on the journey, still on the baby steps”.

Dr Somayeh Taheri, CEO & Chairman of UrbanChain, a multi-award start-up company based in Manchester designing, developing and disseminating blockchain technology for utility services.

Steven Holland, Commercial Director at Thermatic providing an overview of the company’s digital transformation journey through the use of IoT

Internet of Things

Where digitalisation is helping Crystal Doors to boost operational efficiency, other companies are using it to improve their product offering. At the event we heard from Steve Holland, Commercial Director of Salford-based HVAC specialists Thermatic, who are doing just that.

Thermatic provides HVAC installation and maintenance services nationwide. Having identified a problem with server rooms overheating at multiple customer sites, the company needed a system of mobile, Internet of Things (IoT) enabled sensors that could be retrofitted to existing assets to help track and predict overloads remotely. The 4G-connected sensors required were simple, easy to install and low cost, but have had a transformative impact in terms of customer care and competitiveness. As Steve put it himself: “It’s not mind-bending technology, it’s a simple thing that adds value for customers”.

“IoT has been around for years, but the affordability of sensors is now so low that everybody can embrace it”, confirmed one of our other guest speakers Jonathan Custance, Director at bespoke software development consultancy Green Custard. “The first thing is to have a strategy, starting with one or two use cases at first and developing a proof of concept”.

Thermatic is far from the only SME to embed IoT sensors into their products and services. Another example is Genlab, a manufacturer of industrial ovens in Widnes who integrated IoT into their product range with the help of our Manufacturing Growth Fund.

Blockchain

At the other end of the scale, Manchester start-up Urban Chain is an example of a hi-tech company pushing digitalisation to its limits. Founded by alumni from the University of Manchester who studied Blockchain and AI, Urban Chain has developed an innovative platform which directly links energy consumers to energy generators in the wholesale market – enabling easy switching, energy savings and a level playing field for renewable electricity.

Chief Executive Dr Somayeh Taheri was on hand to explain how digital technologies like Blockchain are already disrupting entire markets by taking out the middleman and facilitating safe and secure data sharing in real-time.

Virtual & Augmented Reality

Another much talked-about technology is virtual reality (VR) and its cousin augmented reality (AR). According to a new report from PwC, industrial applications is one of the biggest growth areas for VR and AR, which could deliver a £1.1 trillion boost to the global economy by 2030 and enhance 400,000 jobs in the UK alone.

“Expect VR and AR to skyrocket from the mid-2020s”, said Christopher Whelan, VR/AR and Innovation Marketing Manager at PwC. “If you’ve not tried out VR or AR before, think about the problems in your organisation and these technologies more often than not can offer solutions”.

One of the more useful applications already being used by some of our clients is the ability to create a virtual factory – or ‘digital twin’ – that can be used to map out processes and improve factory layout. Manchester manufacturer MSM aerospace fabricators has recently done just that with the support of Made Smarter, creating a VR simulation of its current and proposed layout for new factory space.

In the long-term, AR is expected to be the more valuable of the two for industry. Whereas VR immerses users in a fully digital environment, AR overlays digital information in the real world. For example, engineers and technicians could be fed information such as repair diagrams using an AR interface, enabling them to follow digital instructions without distracting them from their work.

Director of bespoke software development consultancy Green Custard, Jonathan Custance, explains how SMEs can begin an IoT project and build IoT proof of concepts.

Taking it step-by-step

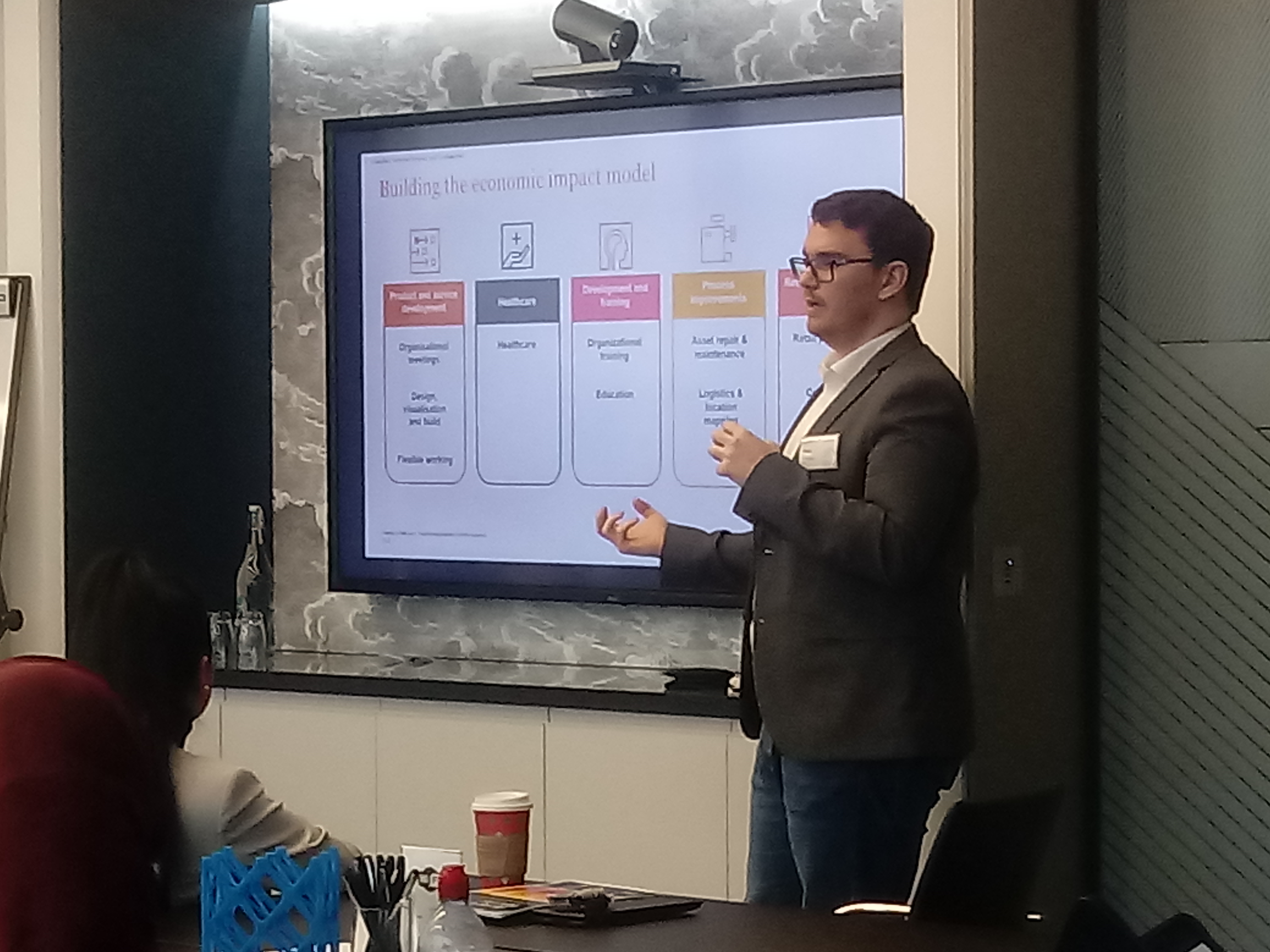

With all these exciting technologies, where do SMEs begin? The journey can be taken step-by-step, explained Philippe Hougardy, Senior Business Development Manager at Amazon Web Services (AWS).

Phillippe spoke about a range of digital manufacturing solutions, including cloud services, IoT, AI, machine learning (ML) and ‘Edge’ computing, which connects devices in a small area without needing to connect them directly to the cloud. IoT in particular is the “new normal”, according to Philippe, with endless applications from enabling Just-In-Time deliveries to monitoring consumables, predicting machine failure, detecting product defects and facilitating ‘control towers’ that visualise data for the boardroom.

Philippe’s advice is to start with simple connectivity and creating quick visualisations and dashboards to “see” what is happening on the factory floor. The next step is “simulating”, using the data to create what-if scenarios, before building predictive capacity (“preparing”) and then finally moving to autonomous operations (“doing as well as predicting”).

What about my business?

With such a wealth of technologies, it can be overwhelming to think about starting on your own journey. The Hub’s specialist manufacturing advisors are on hand to guide you through these steps from start to finish. As Richard Hagan pointed out to our attendees: “Don’t worry about everything at once, just take little steps. And don’t be afraid to ask for help!”

You may also like...

It’s time for manufacturers in Greater Manchester to enhance their problem-solving skills

Ukrainian Research Fellow designs innovative new toy for SEN children

Manufacturing sector in the UK continues to invest and recruit despite a challenging forecast

Get Your Voice Heard: Greater Manchester Manufacturing Blueprint

Creating a Winning Strategy - Fully-funded workshop to help Greater Manchester manufacturers craft a successful sales and marketing plan