We can help you improve your production efficiency

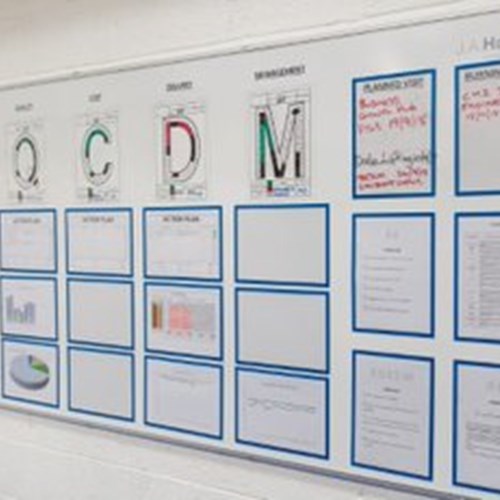

This section provides guidance and tools to help you reduce inefficiencies in your operation using the principles of lean manufacturing.

What is lean manufacturing?

Lean is not a new concept – it has been developed over 150 years and is a mainstay of the world’s leading manufacturers. In essence, lean is a route to eliminating waste – anything that does not advance the process or add value – through a culture of continuous improvement. This suggests that there is always another second to be saved in the process or a step that doesn’t need to be taken – even the slickest operations in the world continue to strive for zero waste.

In this section, you’ll find resources to help you implement these tools in your operation – from real examples from businesses like yours, expertise from lean specialists and factsheets which will simply explain each concept and give a step-by-step guide for you to follow.

Don’t forget, our team of Manufacturing Advisors are fully-funded to work with you to identify which tools will offer the best productivity impacts in your operation.

The Big Question

How to improve productivity in manufacturing?

Resources

Our resources library contains guides to help you implement new techniques, insights from our specialist Manufacturing Advisors and best practice case studies.

Join the Manufacturing Network to access exclusive resources and receive our monthly newsletter, or visit our resources page.

Factsheet

Factsheet

Concepts of Lean Manufacturing

Download factsheet Factsheet

Factsheet

Value Add and 8 Wastes

Download factsheet Factsheet

Factsheet