Bury-based Rakem Group is a leading UK industrial chemical manufacturer and distributor. Launched in 1996, the group has grown to be a toll manufacturer - making formulations to customer specifications, a distributor - of global brands for the coatings, inks, plastics and paper industries and a MAKER - developing existing and creating new formulations in liquid and powder contract manufacturing.

With success came complexity: different teams had evolved their own ways of working, and crucial processes needed to evolve.

Rakem’s Leadership knew they needed to run a value stream mapping exercise but didn’t have anyone internally with the experience to facilitate it.

After finding out the Growth Company offered this service, they invited Martin Hyman, GM Business Growth Hub’s Manufacturing Advisor to provide hands-on, tailored one-to-one support.

Martin sat with cross-functional teams, listened, observed, and led two sessions that helped the company to map the flow of work - from customer enquiry, through trial batches, to scaled production.

Our approach: Tailored 1:1 support, built around their reality:

1. Seeing the whole picture (Process mapping)

We facilitated process mapping workshops that brought together colleagues from sales, technical, production, lab, and logistics. By visualising the current state, teams could see how information flowed, where handoffs stalled, and improvement opportunities. This laid the foundation for a shared language and standardised routes for routine activities.

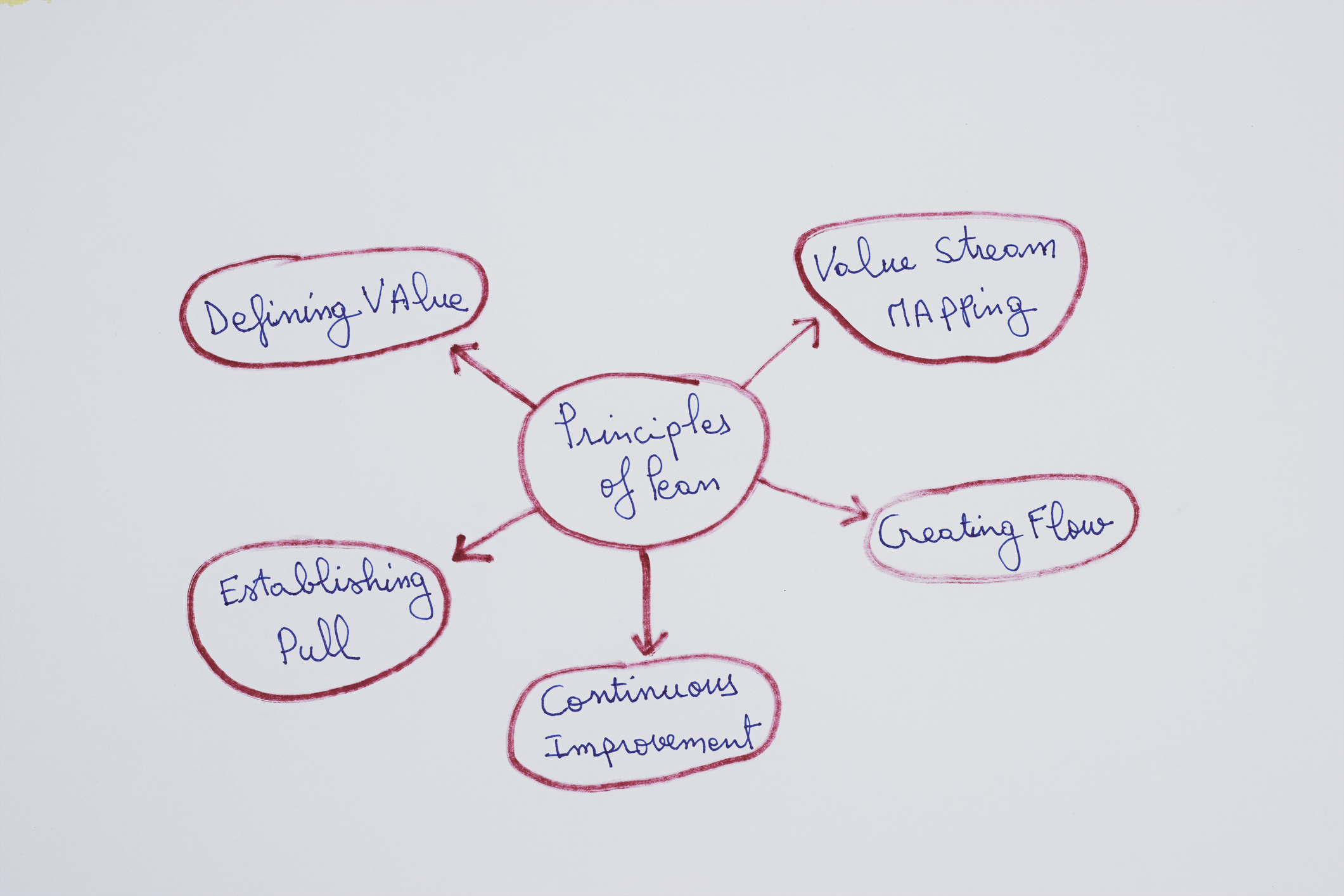

2. Quantifying bottlenecks (Value stream mapping)

Next, we ran a value stream mapping exercise on a significant production process. Step by step from goods-in and storage, to mixing, lab checks, and final dispatch. We captured realistic timings and identified constraints. This made it clear where activities truly added value.

3. Practical improvements (Targeted, doable changes)

Because the support was one-to-one and on site, improvement ideas were rooted in the client’s environment, not theory:

- Material handling and transfer: Opportunities to cut transfer times (e.g., through facilities upgrades already in the company’s plans) and reduce double-handling

- Lab access and coordination: Small changes (e.g., clearer visual signals and direct lab access) to reduce collection delays and queueing

- Standardising cross-department workflows: Moving to one agreed, documented way and training teams to adopt it.

4. Knowledge transfer (Own the method, replicate the wins)

We taught the principles and coached the team to run these methods successfully themselves. The client now has the know‑how to replicate mapping exercises on other processes supporting continuous improvements.

5. Connecting the dots (Broader growth support)

Where helpful, we connected the company to complementary support, e.g. from the Innovation Team and Green Economy teams for funding conversations, sustainability expertise, and invited them to join our cohort Leadership and Culture & Lean Champion workshops, so the operational gains could dovetail with wider business priorities.

The impact: Clarity, confidence, and measurable efficiency

Tailored one-to-one support gave the business confidence to evolve and grow, not just becoming bigger, but better.

- Shared visibility: Teams now have a single, accurate picture of how work flows - enabling better decisions.

- Actionable opportunities: The exercises identified at least 10% efficiency gains through standardisation, smarter hand-offs, and faster turnaround.

- Capacity and profitability: Shorter cycle times mean more through the same assets - raising productive capacity and margin potential.

![]()

Our role was to transfer knowledge on the principles of process and value stream mapping, then coach the team in their own environment to uncover hidden inefficiencies. By doing it together on real lines, we maximised resource use, cut wasted time, and set the client up to own continuous improvement long after the sessions end.

Martin Hyman, Manufacturing Advisor at GM Business Growth Hub

![]()

We weren't aware that this type of support is available and we would absolutely encourage others to make use of it. Martin gave us practical, hands-on support to better understand our business processes and how we can start to identify opportunities to improve efficiency. We plan to replicate value stream mapping exercises for other processes.

Philppa Glover, Managing Director at Rakem Group Ltd

With the core methods embedded, the manufacturer continues to extend mapping to other processes, formalising SOPs across departments, and exploring innovation and sustainability projects that build on the operational gains. The direction is clear: repeatable efficiency, resilient growth.

Speak to our team about tailored one-to-one manufacturing support for all of your strategic and operational challenges; from investment and financial decision-making to sales and marketing, from process mapping and value stream analysis to Leadership and Lean capability-building. We can help you to unlock similar results.