SME manufacturers to upskill workers in AM

18 November 2020

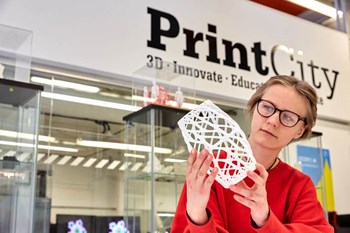

Manchester Metropolitan University’s 3D additive and digital manufacturing hub, PrintCity, will support a cohort of SMEs in an innovative new programme to upskill workforces in additive manufacturing.

The Fast Track Additive Manufacturing Programme aims to give participants a solid grounding in all aspects of AM, from understanding the entire digital workflow end-to-end, to the range of materials that can be used to create products or parts.

The 12-week programme is being delivered in collaboration with Made Smarter and advanced manufacturing specialists Fabricon Design.

Ruth Hailwood, Made Smarter Organisational and Workforce Development Specialist, said:

“This pioneering programme is designed to provide businesses with the skills required to understand what AM technology they should invest in, why they should invest, how they design products for AM and operate the machines, and what benefits they can expect once they have successfully adopted AM. Businesses will provide real-world examples as training material so that the course will address their specific skills gaps.”

3D printing and AM techniques are considered a major growth area for manufacturing, with recent research from HP suggesting that 3D printing is taking centre stage in the digitalisation of industry.

(Credit Manchester Metropolitan University)

Alan Dempsey, Project Manager for PrintCity, explained:

“Businesses across the region are actively exploiting the opportunities presented by AM now more than ever. Many companies have had their businesses disrupted by COVID-19 which has affected staffing, sales, manufacturing and effects to their supply chain. Some companies have used this time to rethink their business model and supply chain, deciding to innovate their traditional workflows with AM and converging design and manufacturing of their products in-house.

“However, many businesses, particularly SMEs, don’t currently have the skills to leverage the benefits of AM. This programme will provide a solid foundation for participants to integrate AM, boosting productivity and growth within their company.”

Companies participating in the programme include Middleton-based MSM aerospace fabricators, which manufacturers parts and assemblies for Airbus and Boeing. Managing Director Michael Pedley said:

“We have identified a need to use AM technology for production templates, laser tooling and checking gauges for inspecting components, and plan to invest in a 3D printer. This will be a great opportunity to develop the design and engineering skills associated with additive manufacturing, which can be shared across the company.”