Innovation and collaboration leaves security firm in safe hands

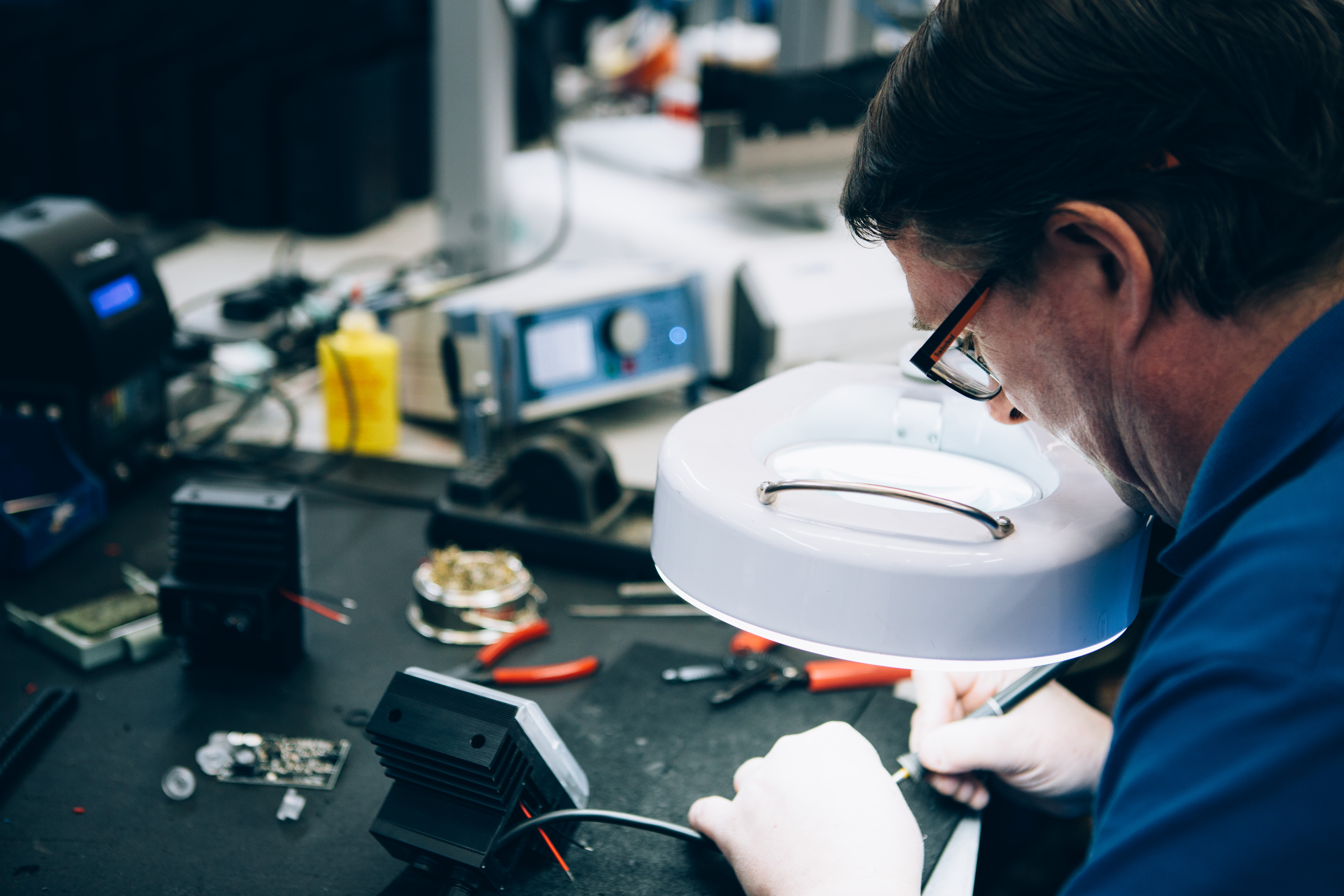

GJD Manufacturing is a leading designer and manufacturer of high precision perimeter detection devices and LED illuminators in Heywood, Rochdale.

Its products provide security for the likes of the Royal Family and Stonehenge, as well as places of worship, schools, homes and businesses around the world.

Watch now: find out more about GJD Manufacturing's business journey in this video

Laser-focused innovation

Back in 2017, Managing Director Mark Tibbenham had identified an opportunity to differentiate GJD from the rest of the market by developing an intelligent laser scanner for drone detection and Back in 2017, Managing Director Mark Tibbenham had identified an opportunity to differentiate GJD from the rest of the market by developing an intelligent laser scanner for drone detection and ground-based threats.

Through GC Business Growth Hub’s partnership with local universities and Innovate UK, Mark was introduced to the concept of a Knowledge Transfer Partnership (KTP). He successfully applied for a 3-year partnership with Manchester Metropolitan University, backed by a grant worth £141,750.

GJD was paired with a postgraduate-level KTP associate from the university, who helped to design a long range scanner with the ability to detect an object within its field of view to an accuracy of just 10cm. The project, which came to an end in 2020, was rated ‘outstanding’ by Innovate UK.

As Mark explains: “This was the first time we’d done a project like this and it was a really good experience. All of the technical transfer from the university, the academic supervisor and our postgraduate, George, were highly beneficial in giving us a competitive edge in our new laser design, which we’ll be launching a new version of before the end of 2022.

The KTP was also beneficial in other ways, Mark continues: “It was nice having the discipline and project management that comes with a KTP in terms of fortnightly and quarterly project reviews. We now use this approach in all the projects we undertake – not only in electrical engineering but in things like purchasing new machinery. There’s a project plan for everything.”

3D printing spin-off

The successful KTP has since led to a spin-off project with Manchester Metropolitan’s PrintCity to leverage the power of 3D printing for new product designs, facilitated with the support of an Innovation Development Manager from the Growth Hub and a £2,000 Innovation Voucher.

The prototype designs are now being used in a new series of products targeted at customers in high-end markets.

“We’d absolutely recommend 3D printing to others,” Mark says. “We initially worked with PrintCity as part of the KTP process to do some 3D prints for mechanical housing, and we’ve since carried on working with them to design some additional products, one of which is just about to launch.

“We’ve also invested in some 3D modelling software of our own that will allow us to create and send files directly to PrintCity if we need to have prototypes made.”

“We’re already back to our pre-COVID turnover”

Like many manufacturers, COVID-19 was a significant challenge for GJD, with sales dropping by 30 per cent at the height of the crisis. However, thanks to its new products, an efficiency drive and a new business strategy, the company has come out of the pandemic in a strong position.

In 2021, the Growth Hub helped GJD to secure a £3,685 Small Business Recovery Grant, which enabled the company to undertake a strategic marketing consultation with an industry expert. The resulting business plan is designed to not only assist GJD’s recovery from COVID-19, but exceed pre-COVID levels of business.

The upside of the pandemic was that we had to find ways to take costs out of the company and be more efficient, which we did. The consultant then helped us to come up with a 3-year business plan that saw us focus in on new export markets.

We still have lots of success with exporting despite ongoing supply chain challenges since the pandemic, and we’re in a much better place as a company – we’re more profitable and already back to pre-COVID turnover.

Mark Tibbenham, Managing Director, GJD Manufacturing

Making the most of the support available

GJD is a perfect example of a business that has readily engaged with the wide range of support on offer from the Growth Hub and its partners.

In 2018, a £3,000 grant from the Growth Hub’s Manufacturing Service allowed members of the senior management team to attend a number of strategic development courses to gain new skills. A year later, the Hub’s Mentoring Service matched Mark with a director from BAE Systems who opened his eyes to a number of new opportunities.

“I went to see BAE Systems’ facility and learnt a lot about alternative materials and composites,” Mark recalls. “We have some very heavy products, so it was really useful to learn about other materials and modelling techniques we could use to make products lighter and more environmentally-friendly – which is a big priority for us going forward.”

GJD has also benefitted from export funding from the International Trade service to expand into new markets, and more recently received grant funding from the Made Smarter programme for new Materials Resource Planning (MRP) software and a student placement project to digitalise stock control.

“Accessing all this support is a must”

Describing his experience working with so many supportive programmes, Mark says: “Accessing all this support is a must for any SME. It always has a positive outcome for us and it’s so easy; the Innovation Development Manager, Dharma, always comes to us when she knows there’s something we can benefit from.

“Once you have that first connection, you’re kept informed of all kinds of possible opportunities. I don’t have to spend time doing my own research about what support and grants are out there because it comes to me directly through Dharma and her colleagues.”

A bright future ahead

Getting onto a much stronger footing following the pandemic saw GJD employ four new staff in 2021, and the company is now re-shoring production to the UK after investing £100,000+ in a new surface mount machine.

Mark is also taking part in the Growth Hub’s Executive Development Programme to further develop his leadership and management acumen, and plans to offer his services to a local school to provide pupils with real-world insight into industry.

Mark concludes: “We continue to be innovative – that’s our big driver. We’ve been quick to recognise the changing needs of the market, and I can’t praise the Growth Company and its partners enough for the support we’ve received along the way.”

Looking to be bring an innovative product to market? Our specialist innovation service will help you identify opportunities, access the region’s leading facilities, evaluate your ideas, and challenge the status quo. Take the next steps, Enquire and Grow today.